PRODUCT INTRODUCTION

PRODUCT CENTER

产品中心

产品简介

PRODUCT FEATURES

产品特点

01

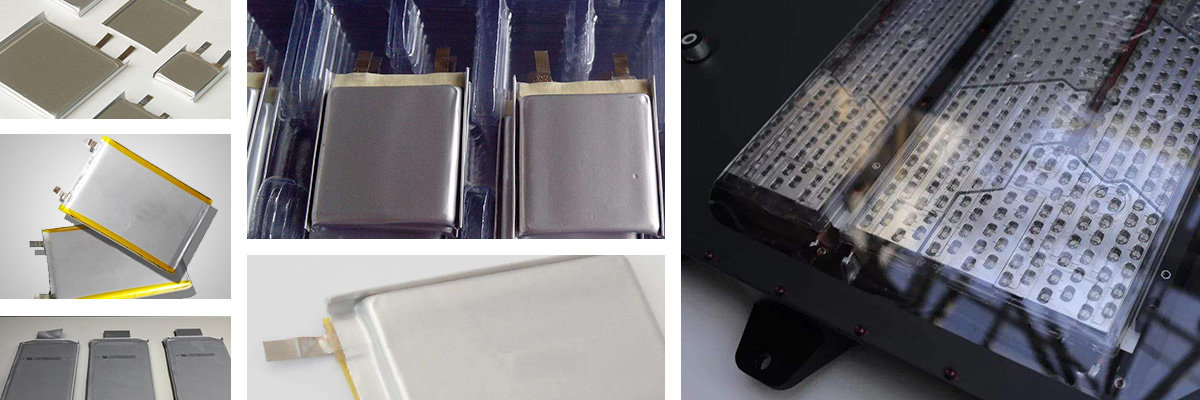

Advantages of soft pack batteries

Category | Aluminum plastic film soft bag | Steel shell, aluminum shell hard pack |

| Safety performance | Safer (when a safety problem occurs, the blast will crack) | Poor safety (easy to explode) |

| Intrinsic performance | Light weight (40% lighter than steel shell, 20% lighter than aluminum shell), small internal resistance, high energy density | Heavy weight, large internal resistance, low energy density |

Service life | Longer cycle life (100 cycles attenuation is 4% -7% less than aluminum shell) | Short cycle life |

| Designability | The design is more flexible, the shape can be changed to any shape, and the design can be thinner | Square or cylindrical |

Consistency | Product performance consistency is relatively poor (resolved by increasing the degree of production automation) | Relatively mature technology and good product consistency |

Cost | High cost (solved by large-scale production) | Relatively low cost |

02

Aluminum plastic film process advantages

| Category | Dry method | Thermal method |

| Preparation | After bonding Al and CPP with adhesive, they are directly pressed together | MPP is used to connect Al and CPP, and then thermally synthesized under the condition of slow heating and green pressure, the production process is longer. And due to long-term high-temperature baking, ALF is embrittled, resulting in deterioration of drawing performance |

Advantage | Deep drawing performance, short circuit resistance performance, appearance (less impurities, pinholes, fish eyes), good cutting performance, simple process | Certainly superior in electrolyte resistance and water resistance |

| Disadvantage | The resistance to electrolyte and water is not as good as thermal method, but the performance can be basically close to thermal method after process improvement | Poor deep drawing performance, poor short-circuit resistance, poor appearance, poor cutting performance |

| Application | Mobile phone batteries, smart wearable batteries, new energy vehicle batteries, high-rate batteries, high-capacity batteries | Used in batteries that do not require high capacity |

PRODUCT MIX

产品结构

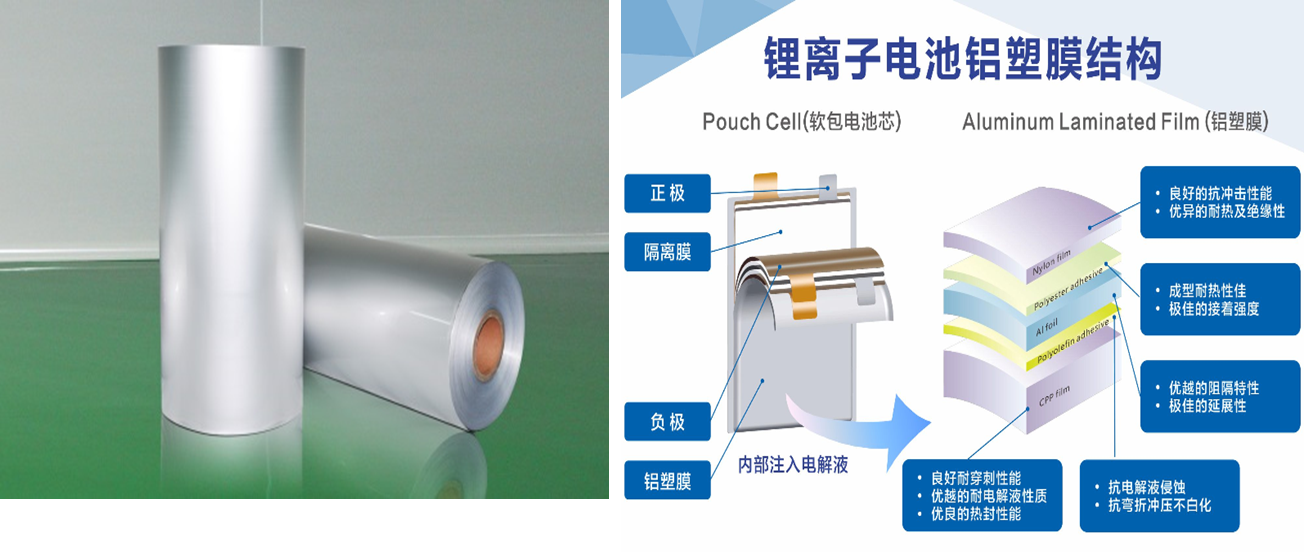

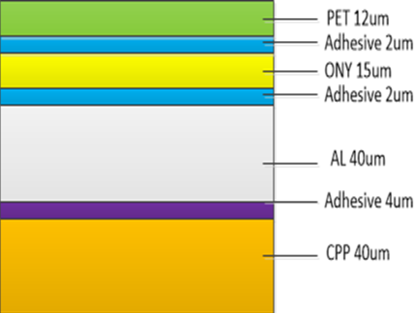

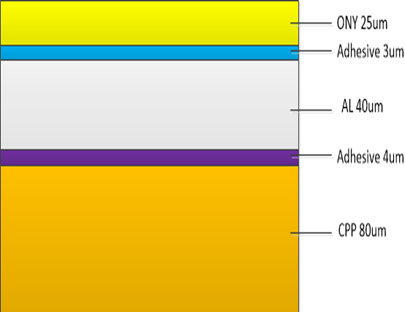

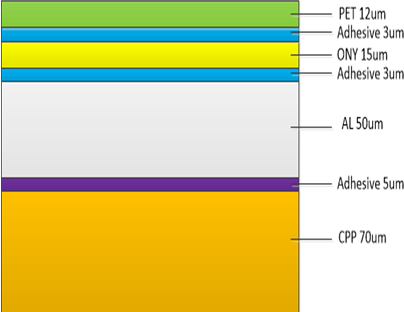

The structure of a typical aluminum plastic film is mainly: ON (surface layer) / Al (aluminum foil layer) / CPP (resin layer). Among them, the outermost layer is usually a nylon layer or a composite layer of PET and nylon, which mainly has the protective function of pollution prevention, corrosion resistance and external damage; the middle aluminum foil layer is the base material, which plays the role of waterproof, barrier and product shape molding; Propylene is the heat-sealing layer, the main function is to seal and bond, and to separate the aluminum layer from the battery core, to prevent the electrolyte leakage of the package and corrode the aluminum foil; the adhesive or adhesive resin composite layer mainly acts as a strong connection between the layers effect.

HG-113

HG-P115

HG-152

HG-P158

PRODUCT PERFORMANCE

基本性能

检测项目 Tested items | 单位 Unit | HG-113 | HG-P115 | HG-152 | HG-P158 | |||||

| 目标值 Target value | 实测值 Measured value | 目标值 Target value | 实测值 Measured value | 目标值 Target value | 实测值 Measured value | 目标值 Target value | 实测值 Measured value | |||

厚 度 Thickness | μm | 113±5 | 112 | 115±5 | 118 | 152±5 | 153 | 158±5 | 156 | |

| 剥离强度(PET/ONY) Laminate strength(PET/ONY) | N/15mm | _ | _ | ≥3 | 不易剥离 | _ | _ | ≥3 | 不易剥离 | |

| 剥离强度(ONY/AL) Laminate strength(ONY/AL) | N/15mm | ≥5 | 不易剥离 | ≥5 | 不易剥离 | ≥5 | 不易剥离 | ≥5 | 不易剥离 | |

| 剥离强度(AL/CPP) Laminate strength(AL/CPP) | N/15mm | ≥8 | 12.5 | ≥8 | 12.6 | ≥12 | 25.6 | ≥12 | 24.7 | |

| 热封强度 Heat seal strength | N/15mm | ≥60 | 105 | ≥60 | 137 | ≥80 | 145.6 | ≥80 | 160.5 | |

| 上下模185℃,0.3Mpa,3s Upper and lower dies at 185℃,0.3Mpa,3s | ||||||||||

| 抗拉强度 Tensile strength | MD | N/15mm | ≥100 | 127 | ≥100 | 126 | ≥110 | 142 | ≥110 | 150 |

| TD | N/15mm | 137 | 130 | 149 | 157 | |||||

| 断裂伸长率 Elongation at break | MD | % | ≥70 | 147 | ≥70 | 119 | ≥80 | 198 | ≥80 | 186 |

| TD | % | 114 | 85 | 165 | 148 | |||||

| 耐电解液性能(EC:DEC:DMC=1:1:1,LiPF6,1M+H2O1000ppm)85℃浸泡24h Electrolyte resistance(EC:DEC:DMC=1:1:1,LiPF6,1M+H2O1000ppm),soaking at 85℃ for 24h | ||||||||||

| 剥离强度(AL/CPP) Laminate strength(AL/CPP) | N/15mm | ≥6 | 11.8 | ≥6 | 10.7 | ≥10 | 18.5 | ≥10 | 19.1 | |

| 热封强度 Heat seal strength | N/15mm | ≥50 | 95 | ≥50 | 88 | ≥60 | 112 | ≥60 | 125 | |

| 上下模185℃,0.3Mpa,3s Upper and lower dies at 185℃,0.3Mpa,3s | ||||||||||

| ROHS检测 ROHS detection | 合 格 Qualified | 合 格 Qualified | 合 格 Qualified | 合 格 Qualified | ||||||

| 外观:无针孔、异物、粘连、复合层间分层及损伤、晶点、气泡、皱褶等缺陷 Appearance : No pinhole,impurity,adhesion,but with obvious delamination and scrtch,crystal spot,bubble,wrinkle and other defects between composite layers. | ||||||||||

PERFORMANCE COMPARISON

性能对比

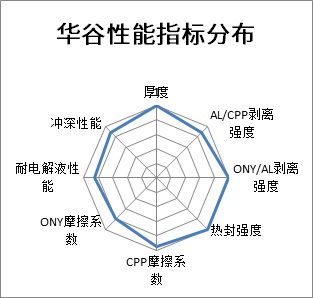

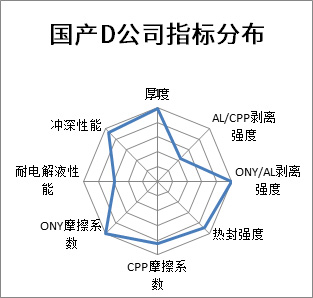

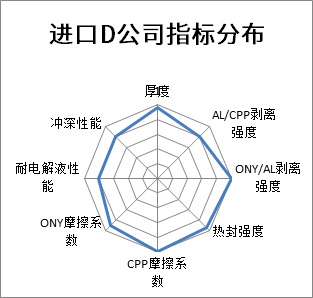

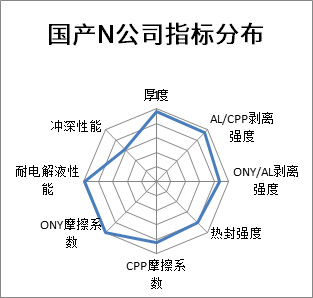

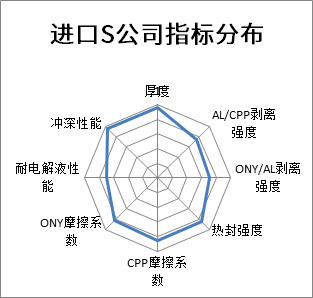

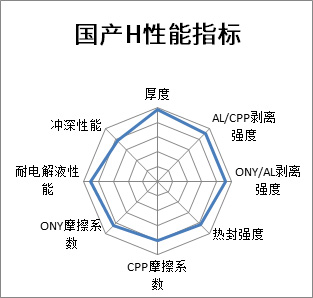

The company's products adopt the most advanced dry process of aluminum-plastic film in the world, and the deep-drawing performance of aluminum-plastic film far exceeds domestic similar products, and is basically close to the performance requirements of Japan's Showa. The electrolyte resistance performance of the dry process aluminum-plastic film is a weak point. Through technology absorption and innovation, product process optimization has significantly improved the electrolyte resistance of the aluminum-plastic film, and has basically reached the electrolyte resistance level of the international thermal process. .